How to Calculate Scope 1 Emissions: A Step-by-Step Guide

Why Scope 1 Matters

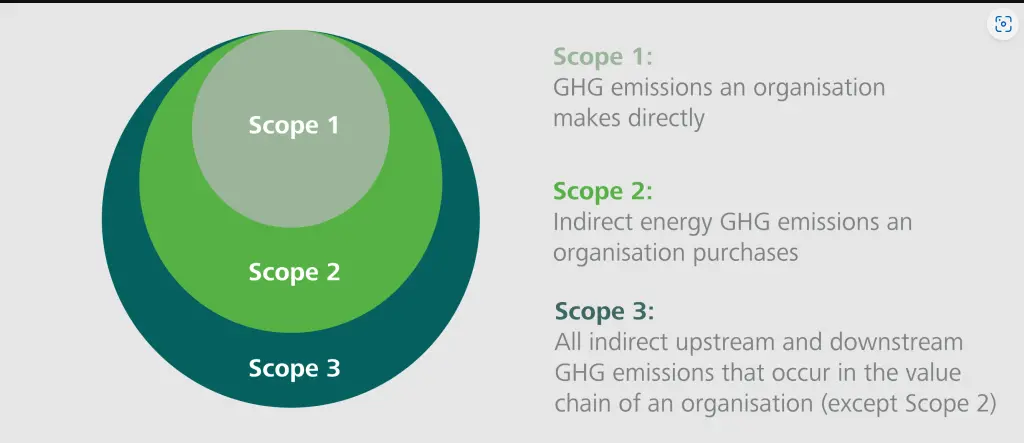

Scope 1 emissions are the direct greenhouse gases

(GHGs) released from sources your company owns or controls. They’re often

the easiest to measure and reduce, making them a critical starting point

for any carbon accounting strategy.

Examples of Scope 1 emissions are:

- Fuel

combustion in company vehicles (gasoline, diesel)

- On-site boilers,

furnaces, or generators (natural gas, coal)

- Fugitive

emissions (refrigerant leaks, methane from waste)

If your business operates vehicles, machinery, or heating

systems, you’re producing Scope 1 emissions—and regulators (like the SEC and

EU) are increasingly requiring disclosure.

Step 1: Identify Your Scope 1 Emission Sources

Compile Emissions Inventory

Before calculating Scope 1 emissions, you need a complete inventory of all direct emission sources in your operations. This "mapping" process ensures you don’t overlook significant contributors (like fugitive methane or backup generators).

|

Category |

What to Look For |

Common Examples |

|

Stationary Combustion |

Fuel burned in fixed equipment |

Boilers, furnaces, backup generators (natural gas,

diesel, coal) |

|

Mobile Combustion |

Fuel burned in vehicles/equipment you own or lease |

Company cars, delivery trucks, forklifts,

construction equipment (gasoline, diesel) |

|

Process Emissions |

GHGs released during industrial processes

(non-combustion) |

Cement production (CO₂ from limestone),

semiconductor manufacturing (PFCs) |

|

Fugitive Emissions |

Unintentional leaks of GHGs from equipment or

systems |

Refrigerant leaks (HVAC), methane from pipelines or

landfills |

Conduct a Facility Walkthrough

- Who

to involve: Facility managers, maintenance staff, fleet operators.

- What

to document: To prepare the inventory list.

- Fuel

types used (e.g., natural gas, propane, diesel).

- Equipment

lists (e.g., boiler models, vehicle registrations).

- Potential

leak points (e.g., refrigerant lines, gas valves).

Tip: Take photos and tag locations on a facility map for

reference.

Review Operational Records

Cross-check your walkthrough with:

- Fuel

purchase receipts (identify diesel, gasoline, natural gas

volumes).

- Equipment

maintenance logs (e.g., refrigerant recharge records = leaks).

- Utility

bills (e.g., natural gas consumption for heating).

Identify "Hidden" Sources

These are often missed but can be significant:

- Emergency

generators (test runs consume fuel).

- Off-road

vehicles (e.g., farm tractors, airport ground support equipment).

- Employee-owned

assets (e.g., leased vehicles under company control).

Red flag: If you operate in cold climates,

include fuel for space heating.

Use a Scope 1 Mapping Template

Create a simple spreadsheet to log sources:

|

Source Type |

Location |

Fuel/Process |

Data Source |

Notes |

|

Boiler #1 |

Main factory |

Natural gas |

Utility bills (m³) |

2,000 m³/year |

|

Delivery van (ID: 45) |

Logistics |

Diesel |

Fuel card (liters) |

5,000 L/year |

|

HVAC system |

Office building |

R-410A refrigerant |

Maintenance logs (kg) |

1.5 kg leaked last year |

Step 2:

Collect Activity Data

Collecting accurate activity data is where

carbon accounting gets real. This step transforms your mapped emission sources

(from Step 1) into quantifiable numbers.

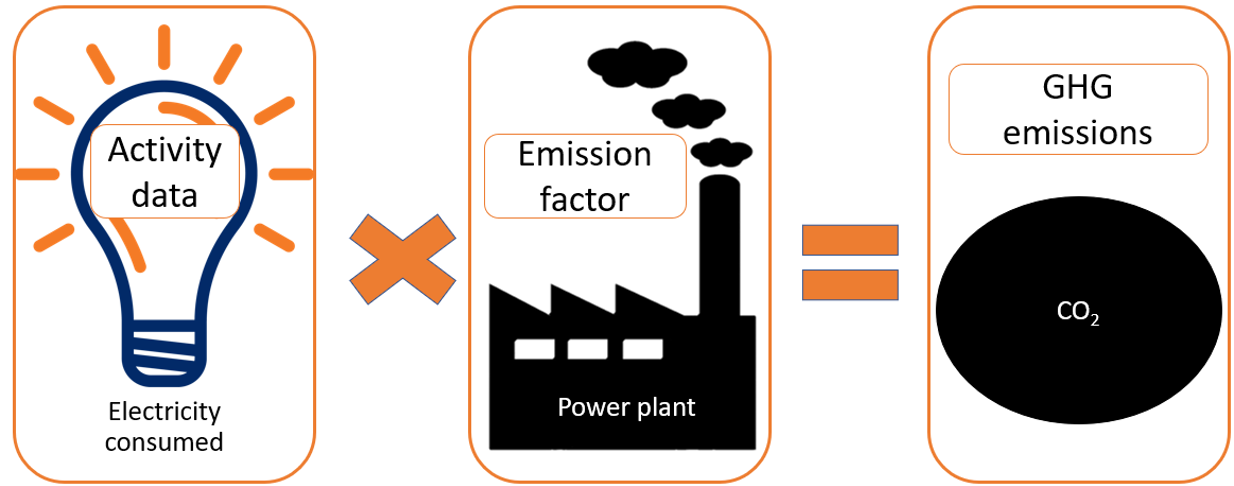

Activity data refers to the measurable inputs that

generate emissions. Think of it as the "raw ingredients" for your

carbon calculations:

|

Emission Source |

Activity Data Needed |

Units |

Where to Find It |

|

Diesel fleet |

Liters of diesel consumed |

Liters or gallons |

Fuel cards, invoices, odometer logs |

|

Natural gas boiler |

Cubic meters (m³) of gas |

m³ or therms |

Utility bills, submeters |

|

Refrigerant leaks |

kg of refrigerant added |

kg |

HVAC maintenance records |

Golden Rule: Always track data in the same units as your emission factors (e.g., liters for diesel, kg for refrigerants).

For example:

1. Fuel Consumption (Mobile & Stationary Combustion)

- Company

Vehicles:

- Source:

Fuel purchase records, GPS fleet data, odometer readings.

- Pro

Tip: If exact data is missing, estimate using:

Fuel Used (L)=Distance Traveled (km)/Vehicle Efficiency (km/L)

*(Example: A van drives 10,000 km/year at 10 km/L → 1,000 L

diesel/year)*

- On-Site

Generators/Boilers:

- Source:

Utility bills, fuel delivery receipts, hour meters.

- Watch

For: Backup generators (often overlooked but used during outages).

2. Process Emissions (Industrial Activities)

- Data

Needed: Material inputs/outputs (e.g., limestone used in cement

production).

- Sources:

- Production

logs (e.g., "X tons of raw material consumed").

- Chemical inventories (e.g., ammonia used in refrigeration).

3. Fugitive Emissions (Leaks & Venting)

- Refrigerants:

- Source:

HVAC service records.

- No

Records?: Use default leak rates (e.g., 10% of total

charge per year).

- Methane

(Oil/Gas):

- Source:

Leak detection surveys, EPA’s GHGRP reports.

With activity data in hand, you’re ready for Step 3: Applying Emission Factors—where we turn liters and kWh into CO₂e.

Step 3:

Apply Emission Factors

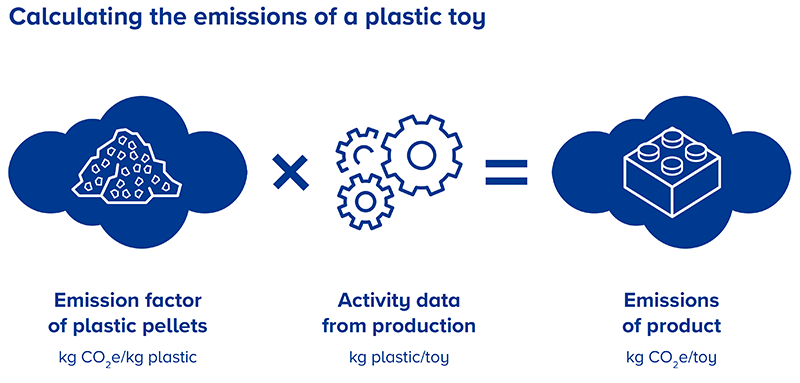

An emission factor (EF) is a standardized

value that tells you:

"How much greenhouse gas is released per unit of

activity?"

Think of it like a nutrition label for carbon:

- 1

gallon of gasoline = 8.89 kg CO₂e (like "1 cookie = 200

calories")

- 1

kWh of grid electricity = 0.5 kg CO₂e (varies by energy source)

- Government

Agencies

- EPA

(U.S.): GHG Emission Factors Hub

- DEFRA

(UK): Conversion Factors Database

- International

Organizations

- IPCC

(UN): Default factors in their Guidelines

- IEA:

Fuel-specific factors for energy

Example Calculation: Diesel-Powered Fleet

- Activity

Data: 10,000 liters of diesel consumed

- Emission

Factor (EPA): 2.68 kg CO₂e per liter

- Total

Emissions:

10,000 L×2.68 kg CO₂e/L = 26,800 kg CO₂e (26.8 metric tons)

Note: If using biofuels, adjust for biogenic CO₂

(often counted as carbon-neutral).

Step 4: Account for Fugitive Emissions

Fugitive emissions are unintentional greenhouse gas

leaks from equipment, pipelines, or industrial processes. Unlike

combustion (which releases CO₂ predictably), fugitives escape

unexpectedly—often as potent gases like methane (CH₄) or refrigerants,

which can be hundreds to thousands of times worse for global

warming than CO₂.

Key Characteristics of Fugitive Emissions

|

Feature |

Why It Matters |

|

Unintentional |

Not from burning fuel, but from leaks, evaporation, or

faulty equipment |

|

High Global Warming Potential (GWP) |

Methane = 28x CO₂; some refrigerants = 3,000–14,000x

CO₂ |

|

Often Overlooked |

Hard to detect without sensors, but can dominate your

carbon footprint |

Common Sources of Fugitive Emissions

- Refrigerants (AC

units, freezers)

- Gases:

HFCs (R-404A), CFCs, HCFCs

- GWP:

Up to 3,922x CO₂ (for R-404A)

- Oil

& Gas Systems

- Methane

leaks from pipelines, valves, fracking

- GWP:

Methane = 28x CO₂ over 100 years (but 84x over 20 years!)

- Landfills

- Decomposing

organic waste → methane

- Industrial

Processes

- Chemical

manufacturing, mining (venting of gases)

Often overlooked, fugitive emissions (e.g., refrigerants) can have high global warming potential (GWP).

How to Calculate Fugitive Emissions (Pre-Example Primer)

The formula adjusts for gas type and leak

rate:

Fugitive Emissions (kg CO₂e) = Leak Amount (kg)×GWP

Variables:

- Leak

Amount: Measured via:

- Maintenance

records (e.g., "Added 5 kg refrigerant this year")

- Infrared

cameras or sensors (for methane)

- GWP:

From IPCC or EPA tables (e.g., R-134a = 1,430x CO₂)

Example Calculation (Refrigerant Leak)

(This sets up your later detailed calculation.)

Scenario: A grocery store’s walk-in freezer

uses R-404A refrigerant.

- Leak

Detected: 3 kg lost over a year

- GWP

of R-404A: 3,922 (from IPCC)

- Calculation:

3 kg×3,922 = 11,766 kg CO₂e

Equivalent to driving a gas car 30,000

miles!

Step 5:

Sum All Sources for Total Scope 1 Emissions

Now that you’ve calculated emissions for each individual

source (e.g., vehicles, boilers, refrigerant leaks), it’s time to roll

them up into your total Scope 1 footprint. This is where your carbon

accounting comes together—but accuracy is critical.

Create a master table compiling all calculated emissions. Use this structure:

|

Emission Source |

Activity Data |

Emission Factor |

Emissions (kg CO₂e) |

|

Diesel fleet (10,000 L) |

10,000 L diesel |

2.68 kg CO₂e/L |

26,800 |

|

Natural gas boiler (5,000 m³) |

5,000 m³ natural gas |

1.96 kg CO₂e/m³ |

9,800 |

|

Refrigerant leak (R-404A) |

2 kg leaked |

GWP = 3,922 |

7,844 |

|

Total Scope 1 Emissions |

44,444 kg CO₂e |

Note: Always include units (kg CO₂e or metric tons CO₂e)

for clarity.

Take note of common mistakes before finalizing:

- Double-counting:

Did you account for the same fuel in both mobile and stationary

combustion?

- Unit

mismatches: e.g., mixing liters and gallons, or kg and tons.

- Missing

sources: Did you include backup generators, off-road equipment, or

fugitives?

Quick Audit Tip:

Compare your total to previous years or industry

benchmarks. If your emissions seem abnormally high/low, revisit

calculations.

Conclusion: Why Mastering Scope 1 Emissions Matters

Calculating your Scope 1 emissions isn’t just a compliance

exercise—it’s the foundation for credible climate action. By

following this step-by-step guide, you’ve learned how to:

- Map all

direct emission sources (from boilers to refrigerant leaks).

- Collect precise

activity data (no more guesswork).

- Apply scientifically

validated emission factors.

- Sum your

total footprint accurately—avoiding costly oversights.

As the old adage goes:

“What gets measured gets managed.”

Now that you’ve measured, it’s time to act. Stay tuned for

our next guide on Scope 2 emissions—where we’ll tackle the hidden footprint in

your electricity bill.

Comments

Post a Comment