How to Calculate Scope 3 Emissions: A Step-by-Step Guide for Beginners

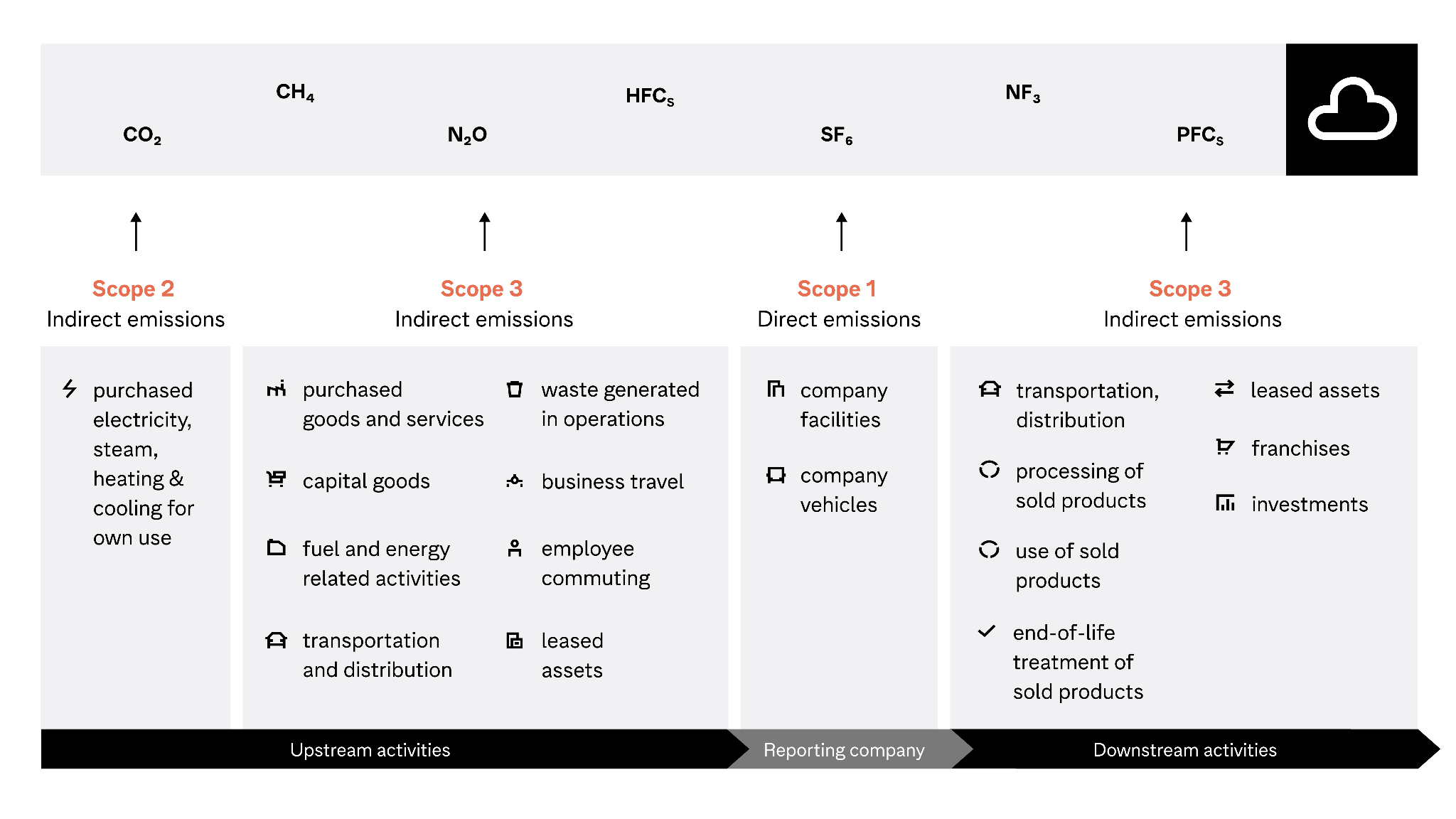

Why Scope 3 Matters

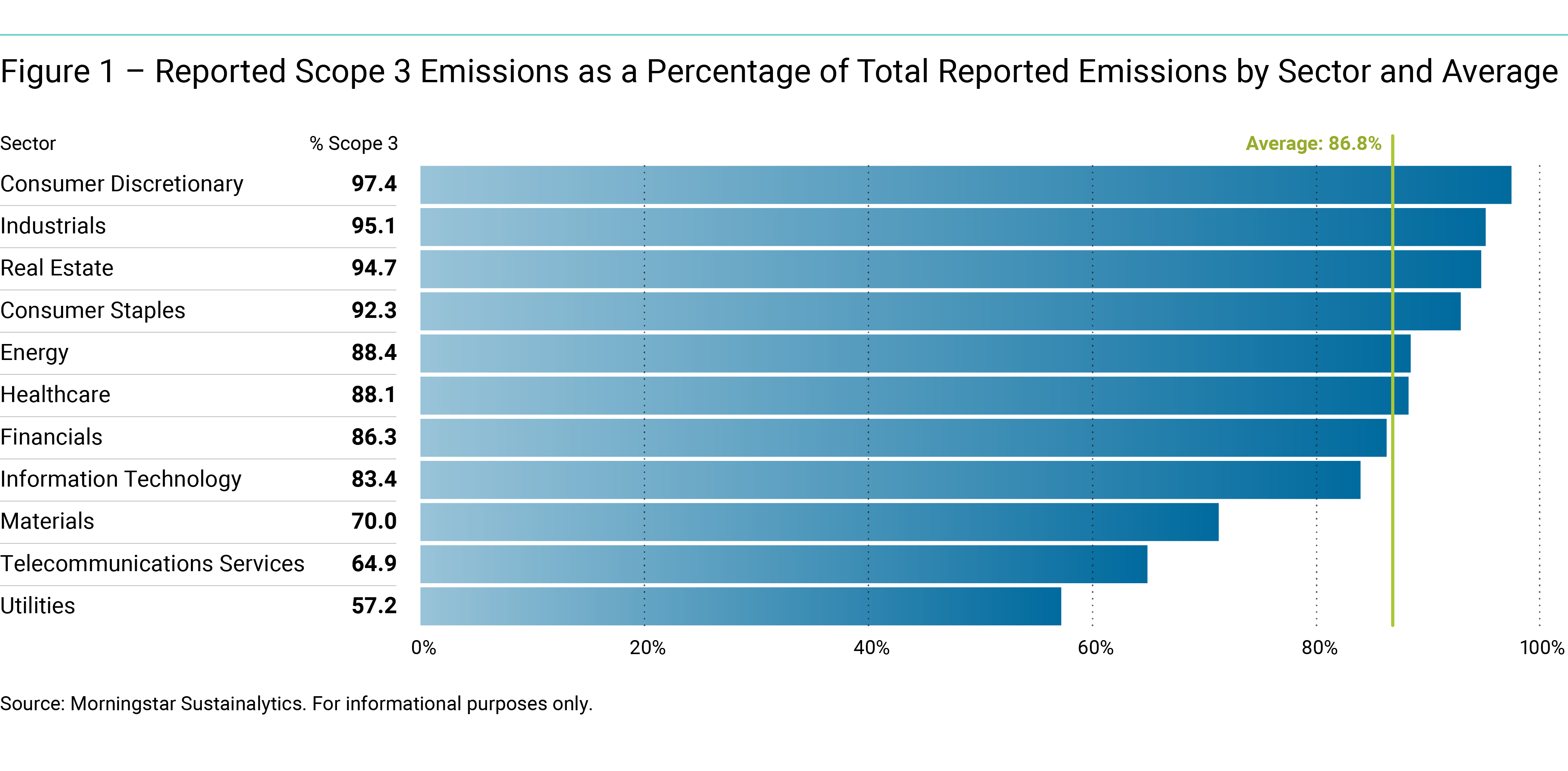

Scope 3 emissions are the hidden carbon

footprint in your value chain—everything from the coffee beans your office

buys to the flights your employees take. They often make up 70-90% of a

company’s total emissions, yet most businesses ignore them.

Examples of Scope 3 activities are:

- Purchased

goods (e.g., raw materials, office supplies)

- Employee

commutes and business travel

- Waste

disposal

- How

customers use your products

If you’ve ever wondered, “Why is our carbon footprint so

high despite going solar?”, Scope 3 is likely the culprit.

Before focusing on the most relevant categories for your

business, it’s essential to understand the full spectrum of Scope 3

emissions as defined by the GHG Protocol. These 15 categories cover

every indirect emission source in your value chain—from raw materials to

product disposal.

Here’s a breakdown of all categories, their significance, and real-world examples:

Upstream

Emissions (Your Supply Chain)

1. Purchased Goods & Services

- What

it includes: Emissions from producing materials, components, and services

you buy.

- Examples:

- Office

supplies (paper, laptops)

- Raw

materials (steel, cotton, plastic)

- Outsourced

services (accounting, marketing)

- Why

it matters: Often the largest Scope 3 category for manufacturers

and retailers.

2. Capital Goods

- What

it includes: Emissions from manufacturing long-term assets (equipment,

machinery, buildings).

- Examples:

- Factory

machines

- Company

vehicles

- IT

servers

- Why

it matters: Significant for industries with heavy machinery (construction,

tech).

3. Fuel- & Energy-Related Activities (Not in Scope

1/2)

- What

it includes: Emissions from producing fuels/electricity you buy (even if

you don’t burn them).

- Examples:

- Extraction

of natural gas for your boilers eg. methane

- Losses

in electricity transmission like heat in power lines

o Diesel

burned by pipelines transporting natural gas to your facility

- Why

it matters: Often overlooked but adds 5–15% to energy

footprints.

4. Upstream Transportation & Distribution

- What

it includes: Emissions from shipping goods to you (by suppliers or

logistics partners).

- Examples:

- Freight

trucks delivering raw materials

- Air

shipping for urgent orders

- Why

it matters: Critical for e-commerce and global supply chains

5. Waste Generated in Operations

- What

it includes: Emissions from disposing of your waste (landfill, recycling,

incineration).

- Examples:

- Food

waste from cafeterias

- Packaging

trimmings

- Why

it matters: Landfill waste emits methane (25x worse than CO₂).

6. Business Travel

- What

it includes: Employee travel (flights, trains, hotels).

- Examples:

- Sales

team flights

- Hotel

stays for conferences

- Why

it matters: A major emissions source for consulting firms and

multinationals.

7. Employee Commuting

- What

it includes: Daily travel to/from work (cars, buses, bikes).

- Examples:

- Gasoline

cars (high emissions)

- Electric

trains (low emissions)

- Why

it matters: Hybrid work has reduced this, but it’s still significant for

offices.

8. Upstream Leased Assets

- What

it includes: Emissions from assets you lease (and don’t own).

- Examples:

- Leased

warehouses

- Rented

company cars

- Why

it matters: Often missed in carbon accounting.

9. Downstream Transportation & Distribution

- What

it includes: Emissions from shipping products to customers.

- Examples:

- Amazon

delivery trucks

- Air

freight for luxury goods

- Why

it matters: E-commerce giants like Shopify track this closely.

10. Processing of Sold Products

- What

it includes: Emissions when customers process your goods (e.g., refining,

cooking).

- Examples:

- A

steel mill’s emissions when making your metal into cars

- A

bakery baking your flour into bread

- Why

it matters: Key for B2B companies selling raw materials.

- What

it includes: Emissions when customers use your product.

- Examples:

- Gasoline

burned in cars you sell

- Electricity

used by your smartphones

- Why

it matters: The #1 category for automakers and electronics

firms.

12. End-of-Life Treatment of Sold Products

- What

it includes: Emissions from disposing/recycling your products.

- Examples:

- Landfilled

plastic packaging

- Recycled

iPhones

- Why

it matters: Fast fashion and tech companies face scrutiny here.

13. Downstream Leased Assets

- What

it includes: Emissions from assets you lease to others (e.g., rental

cars).

- Examples:

- Hertz’s

rental car fleet, Grab’s taxis rented to drivers

- Leased

medical equipment

- Why

it matters: Growing focus in the sharing economy.

14. Franchises

- What

it includes: Emissions from franchisees using your brand.

- Examples:

- McDonald’s

franchise locations

- 7-Eleven

stores

- Why

it matters: Major for global franchises.

- What

it includes: Emissions from companies you invest in.

- Examples:

- A

bank’s carbon footprint from oil/gas loans

- Venture

capital funds backing startups

- Why

it matters: Critical for ESG investors.

Which Categories Should Your Business Prioritize?

|

Industry |

Top 3-5 Categories to Focus On |

|

Manufacturing |

1 (Purchased goods), 4 (Upstream transport), 11 (Product

use) |

|

Retail/E-commerce |

1, 9 (Downstream transport), 12 (Packaging waste) |

|

Tech/Software |

1, 6 (Business travel), 11 (Data center energy use) |

|

Professional Services |

6, 7 (Commuting), 1 (Office supplies) |

Key Takeaways

- Scope

3 is vast—but you don’t need to track all 15 categories at once.

- Start

with high-impact areas (e.g., purchased goods, business travel).

- Use

estimates where data is lacking—it’s better than ignoring them!

Next Step: Choose a calculation method based on

your priority categories.

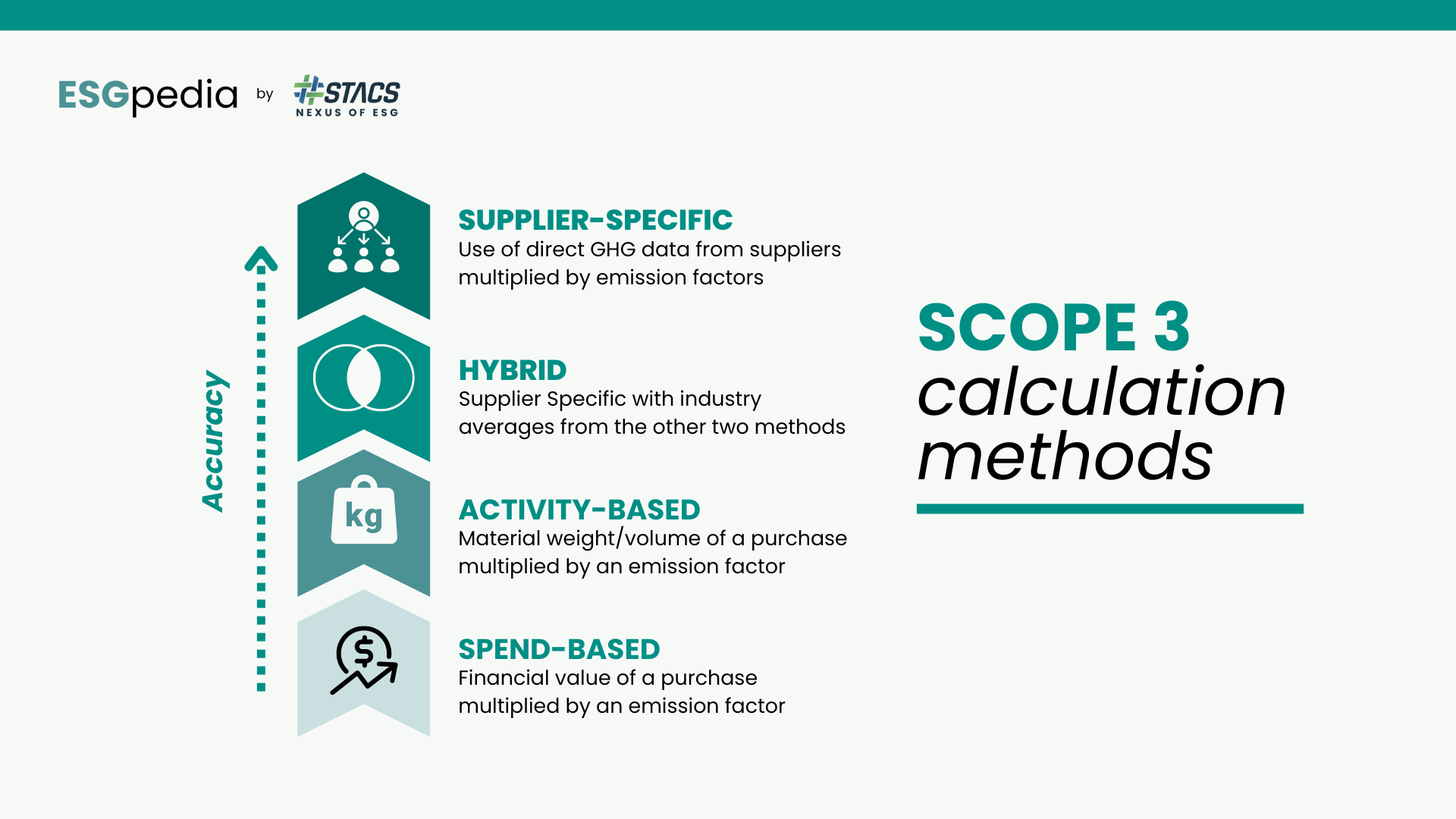

Step 2:

Choosing a Scope 3 Calculation Method

Calculating Scope 3 emissions requires selecting the right

method based on data availability and accuracy needs. Below, we

explain the three primary approaches, their formulas, and real-world examples

to help you decide which is best for your business.

1.

Spend-Based Method (Simplest)

What It Is

Estimates emissions using financial spending

data multiplied by industry-average emission factors (per dollar

spent).

When to Use It

✔ Small businesses with limited

supplier data

✔ Quick initial assessments

✔ Low-priority categories (e.g., office supplies)

Formula

Emissions (kg CO₂e) =

Money Spent ($) × Emission Factor (kg CO₂e/$)

Example

- Activity:

Spent $50,000 on laptops last year.

- Emission

Factor: 0.5 kg CO₂e per $1 spent on electronics (from EPA EEIO).

- Calculation:

$50,000 × 0.5 kg CO₂e/$ = 25,000 kg CO₂e (25 metric tons)

Pros

& Cons

|

Pros |

Cons |

|

✅ Fast, low-effort |

❌ Less accurate (uses averages) |

|

✅ No supplier engagement needed |

❌ Misses supplier-specific

efforts (e.g., renewable |

2. Hybrid

Method (Balanced Approach)

What It Is

Combines supplier-specific data (where available) with spend-based

estimates for the rest.

When to Use It

✔ Mid-sized businesses with some

supplier collaboration

✔ High-impact categories (e.g., raw materials)

Formula

Total Emissions=(∑Supplier-Specific Data) + (∑Spend-Based Estimates)

Example

- Activity:

Purchased $200,000 worth of steel last year.

- Supplier

A (provides carbon data): 100 tons steel × 1.85 kg CO₂e/kg

= 185,000 kg CO₂e.

- Supplier

B (no data): $100,000 × 0.3 kg CO₂e/$ (industry avg.) = 30,000

kg CO₂e.

- Total:

185,000 kg + 30,000 kg = 215,000 kg CO₂e (215 metric tons)

Pros & Cons

|

Pros |

Cons |

|

✅ More accurate than

spend-based |

❌ Requires supplier engagement |

|

✅ Flexible for partial data |

❌ Still uses estimates for gaps |

3.

Physical Unit Method (Most Accurate)

What It Is

Calculates emissions using actual quantities (kg,

liters, km) multiplied by physical emission factors.

When to Use It

✔ Large companies with detailed

supplier data

✔ High-stakes categories (e.g., product lifecycles)

Formula

Emissions (kg CO₂e)=Quantity Used×Emission Factor (kg CO₂e/unit)

Example

- Activity:

Shipped 10,000 kg of goods via air freight.

- Emission

Factor: 8.5 kg CO₂e/kg of air freight (from DEFRA).

- Calculation:

10,000 kg × 8.5 kg CO₂e/kg = 85,000 kg CO₂e (85 metric tons)

Pros

& Cons

|

Pros |

Cons |

|

✅ Highest accuracy |

❌ Requires granular data |

|

✅ Recognized by auditors |

❌ Time-intensive to collect |

How to

Choose the Right Method

|

Factor |

Spend-Based |

Hybrid |

Physical Units |

|

Effort Required |

Low |

Medium |

High |

|

Data Needs |

Only $ spent |

Partial supplier data |

Full supplier data |

|

Best For |

SMEs, early stages |

Growing businesses |

Large enterprises |

Real-World Example: Patagonia’s Hybrid Approach

- Spend-based:

Used for low-impact items (e.g., office supplies).

- Physical

units: Tracked cotton, nylon, and freight emissions per kg.

- Result:

Identified that 83% of emissions came from raw materials, leading to

a switch to organic cotton.

Step 3:

Finding Emission Factors for Scope 3 – The Ultimate Guide

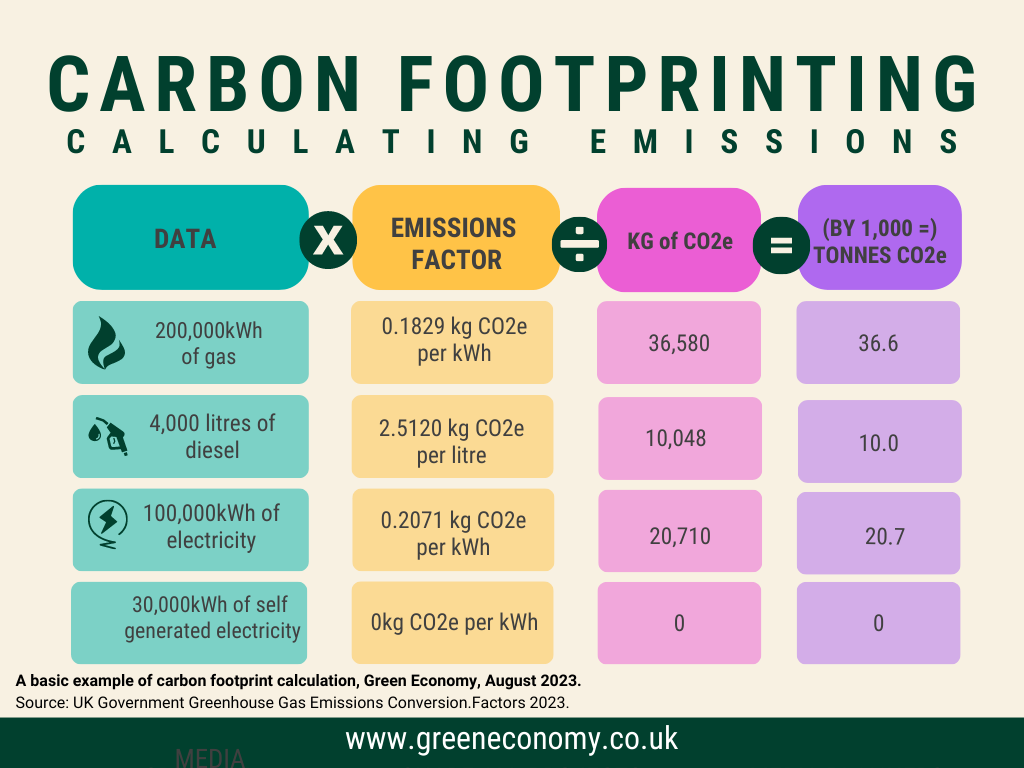

Emission factors (EFs) are the "conversion rates" that turn your business activities (like shipping goods or buying materials) into measurable carbon emissions. Choosing the right factors is critical for accurate Scope 3 accounting.

1. Types

of Scope 3 Emission Factors

A. Spend-Based Factors

- What

they do: Convert dollars spent into CO₂e (kg CO₂e per $1).

- Best

for: Categories like purchased goods/services (Category 1), capital goods

(Category 2).

- Sources:

- EPA's EEIO Database (U.S.-specific)

- EXIOBASE (global,

multi-regional)

Example:

- 100,000spentonmarketingservices×0.2kgCO2e/ (EEIO

factor) = 20,000 kg CO₂e

B. Physical Unit Factors

- What

they do: Convert measurable units (kg, km, kWh) into CO₂e.

- Best

for: Transportation, material use, energy.

- Sources:

- DEFRA UK (transport, materials)

- Ecoinvent (paid,

but gold-standard for LCAs)

- IPCC

Emission Factor Database

Example:

- 10,000

kg of steel purchased × 1.85 kg CO₂e/kg = 18,500 kg CO₂e

C. Activity-Specific Factors

Specialized factors for common business activities:

|

Activity |

Sample Factor |

Source |

|

Air travel (economy) |

0.15 kg CO₂e/passenger-km |

DEFRA |

|

Sea freight |

0.01 kg CO₂e/tonne-km |

GLEC Framework |

|

Landfill waste |

0.1 kg CO₂e/kg |

EPA WARM Model |

|

Employee commuting |

0.2 kg CO₂e/km (gasoline car) |

DEFRA |

2. Where

to Find Reliable Factors

Free Databases

- General

Materials & Services

- EPA EEIO (U.S. $→CO₂e)

- European

Commission EF Database

- Transportation

- DEFRA UK (air, road, rail)

- GLEC

Framework (freight-specific)

- Energy

& Waste

- EPA WARM Model (waste

emissions)

- IEA Country Factors (electricity

by nation)

Paid Databases (More Detailed)

- Ecoinvent:

~$2,000/year but covers 10,000+ materials

- GaBi:

Popular for product lifecycles

- SimaPro:

Used by Fortune 500s for LCAs

3. How to

Select the Right Factor

Follow this decision tree:

- Is

supplier-specific data available?

- Yes

→ Use their reported factor (most accurate)

- No

→ Proceed to step 2

- Can

you measure physical units (kg, km, kWh)?

- Yes

→ Use physical unit factors (e.g., DEFRA for transport)

- No

→ Use spend-based factors (e.g., EPA EEIO)

- Does

the factor match your region/year?

- Always

prefer localized and recent factors (e.g., 2023 U.S.

factors vs. 2015 global averages)

4. Applying Factors Correctly

Example 1: Shipping Goods (Physical Units)

- Activity:

5,000 kg shipped 500 km by truck

- Factor:

0.1 kg CO₂e/tonne-km (from GLEC)

- Calculation:

5 tonnes × 500 km×0.1 kg CO₂e/tonne-km=250 kg CO₂e

- Activity:

10 employees fly 2,000 km each (economy)

- Factor:

0.15 kg CO₂e/passenger-km (DEFRA)

- Calculation:

10×2,000×0.15=3,000 kg CO₂e (3 metric tons)

Example 3: Purchased Goods (Spend-Based)

- Activity:

$200,000 spent on plastic components

- Factor:

0.4 kg CO₂e/$ (EPA EEIO for plastics manufacturing)

- Calculation:

$200,000×0.4=80,000 kg CO₂e (80 metric tons)

Real-World Example: IKEA's Approach

- Uses physical

unit factors for wood, cotton, and transport.

- Uses spend-based for

low-impact items like office supplies.

- Publishes

all factors in their Sustainability Report for transparency.

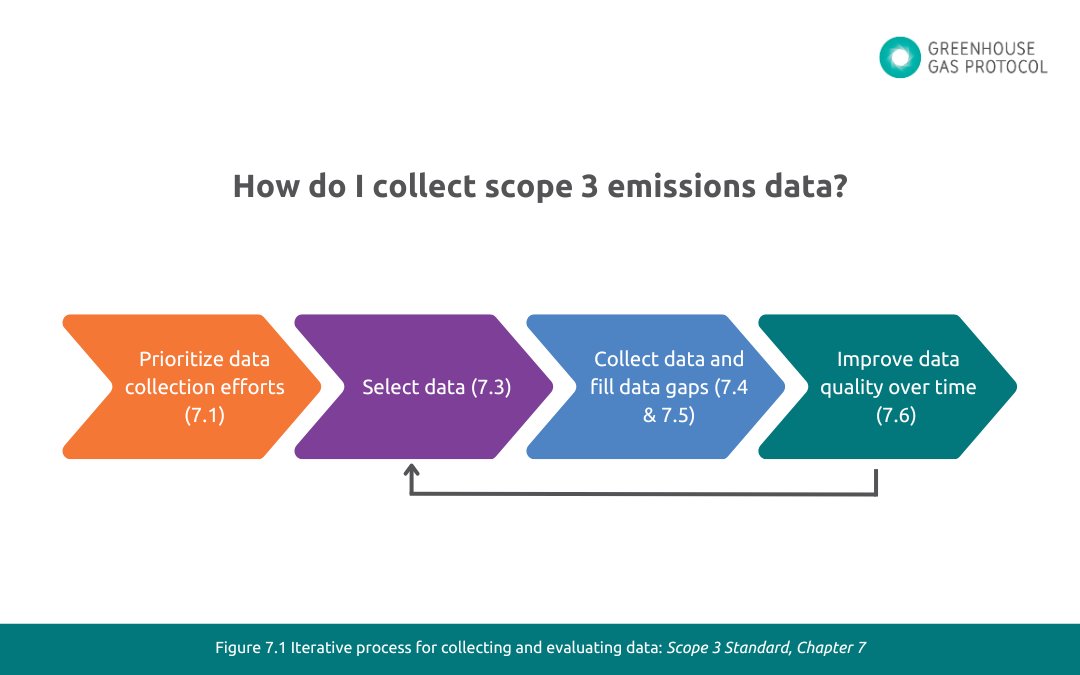

Step 4:

Collecting Scope 3 Data

Collecting data for Scope 3 emissions can feel overwhelming,

but it doesn’t have to be. Here’s how to gather what you need without

losing your mind, prioritized by feasibility and impact.

1. Start With the "Big Rocks" (Highest-Impact Categories)

Focus on 3-5 categories that typically

contribute 80% of Scope 3 emissions for your industry:

|

Industry |

Top Categories to Prioritize |

Where to Find Data |

|

Manufacturing |

1 (Purchased goods), 4 (Transport), 11 (Product use) |

Supplier invoices, logistics records |

|

Retail/E-commerce |

1, 9 (Downstream transport), 12 (Packaging waste) |

Procurement spend, shipping contracts |

|

Tech/Office-Based |

6 (Business travel), 7 (Commuting), 1 (IT hardware) |

Expense reports, HR surveys |

Pro Tip: Use the Pareto Principle – 20% of

effort will cover 80% of your footprint.

2. Data Collection Strategies by Category

A. Purchased Goods & Services (Category 1)

Low-Effort Approach (Spend-Based):

- Pull annual

spend data by category from accounting software (QuickBooks, SAP).

- Apply EPA

EEIO factors (kg CO₂e per $ spent).

Example:

- $500,000

spent on "electronic equipment" × 0.3 kg CO₂e/$ = 150,000

kg CO₂e.

Higher-Accuracy Approach:

- Ask top

5 suppliers (by spend) for carbon data via a simple email:

"Hi [Supplier], as part of our sustainability

efforts, could you share the carbon footprint (kg CO₂e) per unit/product you

supply us? Even rough estimates help!"

B.

Business Travel (Category 6)

Automated Method:

- Use corporate

card data (Amex, Concur) or travel platforms (TripActions).

- Multiply flight

miles × DEFRA factors (e.g., 0.15 kg CO₂e/km for economy).

Manual Method (No Tech Tools):

- Sample 3

months of travel, extrapolate annually.

Example:

- 100

flights × 1,000 km × 0.15 kg CO₂e/km = 15,000 kg CO₂e.

C. Employee Commuting (Category 7)

Simple Survey Template:

1. How do you commute? (Car, bus, bike, etc.)

2. Average round-trip distance: ____ km/miles

3. Days worked onsite/week: ____

· Use DEFRA

factors (e.g., 0.2 kg CO₂e/km for gas cars).

Example:

· 50

employees × 20 km/day × 220 days × 0.2 kg CO₂e/km = 44,000 kg CO₂e.

D.

Transportation & Distribution (Categories 4 & 9)

For Logistics Partners:

- Request total

tonne-km shipped (weight × distance) from carriers.

- Apply GLEC

factors (e.g., 0.1 kg CO₂e/tonne-km for trucking).

No Partner Data? Estimate:

- #

of shipments/year × average distance × typical truck capacity.

Pro Tips to Avoid Burnout

✅ Start with 1-2

categories (e.g., travel + purchased goods).

✅ Use estimates for now – refine later (e.g., "60%

of shipments are by truck").

✅ Leverage existing reports (AP records, fuel cards,

utility bills).

✅ Set a time limit (e.g., "2 hours/week for 4

weeks").

Real-World

Example: How Patagonia Simplified

- Focused

first on cotton, nylon, and freight (biggest impacts).

- Used:

- Supplier

data for key materials

- Spend-based for

everything else

- Cut

data collection time by 70% while capturing 90% of emissions.

Step 5:

Calculating & Summing Scope 3 Emissions

Now that you’ve collected data and emission factors, it’s

time to crunch the numbers. Here’s how to calculate emissions for each category

and roll them up into a total Scope 3 footprint—without overcomplicating it.

1. The

Basic Calculation Formula

For each activity in your prioritized categories,

use:

Emissions (kg CO₂e)=Activity Data × Emission Factor

Variables:

- Activity

Data: Quantity (kg, km, $) from Step 4.

- Emission

Factor: kg CO₂e per unit (from Step 3).

2.

Category-by-Category Examples

A. Purchased Goods (Category 1)

Method: Spend-based

- Data:

$200,000 spent on office furniture.

- Factor:

0.4 kg CO₂e/$ (EPA EEIO for "furniture manufacturing").

- Calculation:

$200,000 × 0.4 = 80,000 kg CO₂e (80 metric tons)

B. Business Travel (Category 6)

Method: Physical units

- Data:

50 flights × 1,500 km each (economy class).

- Factor:

0.15 kg CO₂e/km (DEFRA).

- Calculation:

50 × 1,500 × 0.15 = 11,250 kg CO₂e (11.25 metric tons)

C. Employee Commuting (Category 7)

Method: Hybrid

- Survey

Data:

- 30

employees drive 20 km/day × 220 days/year = 132,000 km.

- 20

employees take trains (10,000 km total).

- Factors:

- Car:

0.2 kg CO₂e/km (gasoline).

- Train:

0.05 kg CO₂e/km (DEFRA).

- Calculation:

(132,000×0.2) + (10,000×0.05 )= 26,400 + 500 = 26,900 kg CO₂e

Summing All Categories

Create a master table to tally your total Scope 3 emissions:

|

Category |

Emissions (kg CO₂e) |

Notes |

|

1. Purchased goods |

80,000 |

Spend-based estimate |

|

6. Business travel |

11,250 |

Flight distances × DEFRA |

|

7. Employee commuting |

26,900 |

Survey data × transport modes |

|

Total Scope 3 |

118,150 (118.15 t) |

Handling Partial Data

Don’t have full-year data? Use:

- Sampling:

Calculate 1 month × 12 (adjust for seasonality).

- Proxies:

If missing a facility, apply data from a similar one.

Example:

- Only

have Q1 shipping data? Assume Q1 = 25% of annual volume.

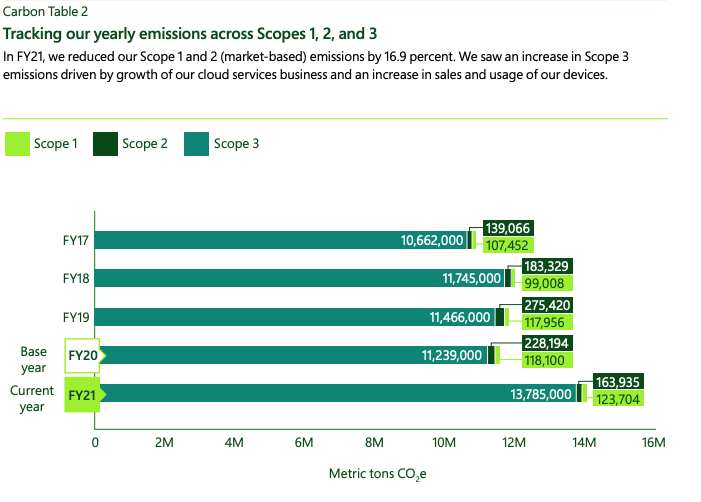

Real-World Example: Microsoft’s Approach

- Physical

units for high-impact categories (e.g., cloud hardware).

- Spend-based for

low-priority spend (e.g., office supplies).

- Total

Scope 3 (2023): 15.3 million metric tons (78% of total footprint).

Calculating Scope 3 emissions isn’t just a compliance exercise—it’s a strategic superpower. By following this guide, you’ve learned how to:

- Identify

your high-impact categories (like purchased goods, travel, and

logistics).

- Gather

data without perfectionism (using spend-based estimates, surveys, and

sampling).

- Apply

the right emission factors (from trusted sources like EPA, DEFRA, or

suppliers).

- Calculate

and sum emissions to see your total value chain footprint.

Do remember, you can:

1.

Start small, improve yearly: Even rough

estimates are better than nothing.

2.

Engage suppliers: Simple emails can yield carbon

data for your biggest spends.

3.

Set reduction goals: Align with

the Science-Based Targets initiative (SBTi) for credibility.

"Scope 3 is where the real carbon footprint hides—and

where the most impactful changes happen."

You’ve now got the tools to measure it. The next step?

Reduce it. Whether through supplier partnerships, cleaner logistics, or product

redesign, your Scope 3 work will separate the leaders from the laggards.

Comments

Post a Comment